PRODUCTS

Machinery

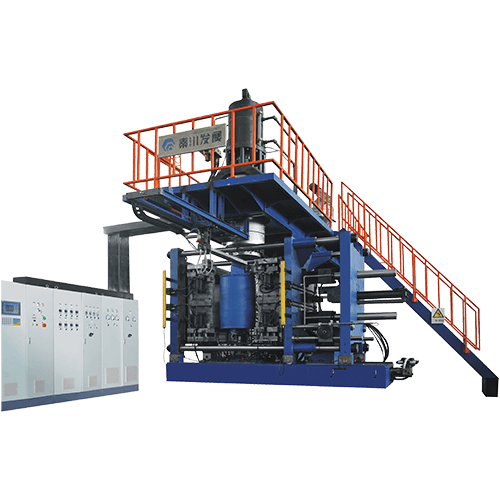

SCJ1500/SCJ1000 Blow Molding Machine

Applications

To make high molecule weight High Density Polyethylene (HMW-HDPE) intermediate bulk container (IBC), pallet, large-sized automobile fuel tank, etc. The maximum container volume is 1500 L.

System Characteristics

- Electric Control System

- Utilizing OMRON multifunction PLC to control processing sequence.

- To set, modify, and monitor data through touch screen panel.

- Using our original 100 point axis wall thickness control system with option to upgrade to a PWDS radial wall thickness control system.

- Utilizing Eurotherm DC speed controller, which is stable, reliable and energy efficient.

- Hydraulic System

- Utilizing proportional servo system and two groups of accumulators. Pumps and valves are all brand name products. The specialty is energy saving technology.

- Pneumatic System

- Utilizing special blowing processing so that air amount and pressure is steadily controlled during the production. Pneumatic elements are brand name products.

- Clamping Unit

- Utilizing patented mechanism, which has no pulling rods (Patent No.ZL00226990), and four pull studs so that large uniform clamping force can be applied and large mold platens can be used to make large containers. Also, it is easy to change mold.

- Blow Molding System

- Utilizes a high efficient extruder for homogenous, high output and quality. The extruder screw and die head are designed and manufactured with CAD/CAE/CAM tools and experience. The steel for the die is 38CrMoAlA.

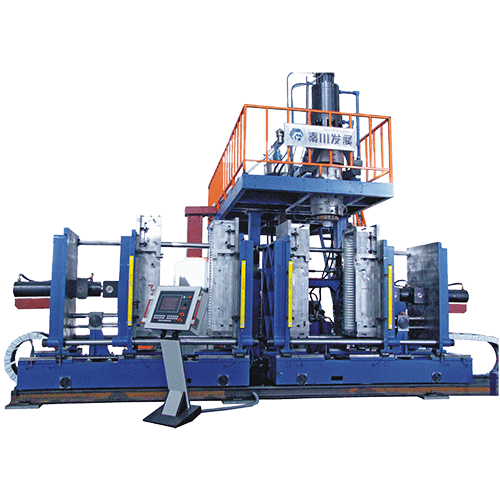

SCJC230x2 Extrusion Blow Molding Machine System

Applications

SCJC230×2 is to make high molecule weight High Density Polyethylene (HMW-HDPE) containers, especially double and single L-ring barrels. The maximum container volume is 230 L.

SCJC230x2 is to make double layer containers for food and liquid chemical packaging with hygiene and sanitation requirements.

System Characteristics

- Electric Control System

- Utilizing OMRON multifunction PLC to control processing sequence.

- To set, modify, and monitor data through touch screen panel.

- Using our original 100 point axis wall thickness control system with option to upgrade to a PWDS radial wall thickness control system.

- Utilizing Eurotherm DC speed controller, which is stable, reliable and energy efficient.

- Hydraulic System

- Utilizing proportional servo system and multi groups of accumulators. Pumps and valves are all brand name products. The specialty is energy saving technology.

- Pneumatic System

- Utilizing special blowing processing so that air amount and pressure is steadily controlled during the production and the L-ring can be formed. Pneumatic elements are brand name products.

- Advanced Die Design System

- SCJC230x2 double layer blow molding machine has an advanced two-layer die design and compact structure. The inside layer uses resin without color and the outside layer can be colored with proper additives based on the requirements.

- Wall Thickness Control System

- The PWDS radial wall thickness control system can be equipped according to customer’s requirements.

- Clamping Unit

- Utilizes 3-platen 4-pulling rod structure so that large uniform clamping force can be applied. Also, it is easy to change mold.

- Blowing Unit

- Versatile with features like expanding, stretching and pulling, diameter locking and blow pin rotation, etc.

- Blow Molding System

- Utilizes a high efficient extruder for homogenous, high output and quality. The extruder screw and die head are designed and manufactured with CAD/CAE/CAM tools and experience. The steel for the die is 38CrMoAlA.

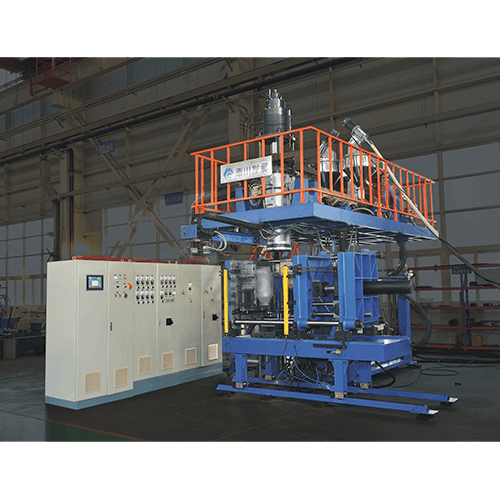

SCJ230B/SCJ230C/SCJ230T Extrusion Blow Molding Machine System

Applications

SCJ230B/SCJ230C/SCJ230T is to make high molecule weight High Density Polyethylene (HMW-HDPE) containers, especially double and single L-ring barrels. The maximum container volume is 230 L.

System Characteristics

- Electric Control System

- Utilizing OMRON multifunction PLC to control processing sequence.

- To set, modify, and monitor data through touch screen panel.

- Using our original 64 points axis wall thickness control system with option to upgrade to a PWDS radial wall thickness control system.

- Utilizing Eurotherm DC speed controller, which is stable, reliable and energy efficient.

- Hydraulic System

- Utilizing proportional servo system and two groups of accumulators. Pumps and valves are all brand name products. The specialty is energy saving technology.

- Pneumatic System

- Utilizing special blowing processing so that air amount and pressure is steadily controlled during the production and the L-ring can be formed. Pneumatic elements are brand name products.

- Wall Thickness Control System

- The PWDS radial wall thickness control system can be equipped according to customer’s requirements.

- Clamping Unit

- Utilizes 3-platen 4-pulling rod structure so that large uniform clamping force can be applied. Also, it is easy to change mold.

- Blowing Unit

- Versatile with features like expanding, stretching and pulling, diameter locking and blow pin rotation, etc.

- Blow Molding System

- Utilizes a high efficient extruder for homogenous, high output and quality. The extruder screw and die head are designed and manufactured with CAD/CAE/CAM tools and experience. Double runners design, easy to change color, high quality parison. The steel for the die is 38CrMoAlA.

SCJ120B Extrusion Blow Molding Machine

Applications

SCJ120B is to make high molecule weight High Density Polyethylene (HMW-HDPE) containers and automobile fuel tanks. The maximum container volume is 120 L.

System Characteristics

- Electric Control System

- Utilizing KOYO multifunction PLC to control processing sequence.

- To set, modify, and monitor data through touch screen panel.

- Using our original 64 point axis wall thickness control system.

- Utilizing Eurotherm DC speed controller, which is stable, reliable and energy efficient.

- Hydraulic System

- Utilizing proportional servo system and two-way flow pump. Pumps and valves are all brand name products. The specialty is energy saving technology.

- Pneumatic System

- Utilizing special blowing processing so that air amount and pressure is steadily controlled during the production and different structured containers can be made, such as open barrel, closed barrel and fuel tank. Pneumatic elements are brand name products.

- Clamping Unit

- Utilizes U-shape structure. It is easy to change mold.

- Blowing Unit

- Versatile with features like expanding, stretching and pulling, large hole blowing, etc. It can be equipped according to customer requirements.

- Blow Molding System

- The extruder screw and die head are designed and manufactured with CAD/CAE/CAM tools and experience. Double runners design, easy to change color, high quality parison.The steel for the die is 38CrMoAlA.

SCJ120C×2 Extrusion Blow Molding Machine System

Applications

To make high molecule weight High Density Polyethylene (HMW-HDPE) containers and inner container of solar water heater. With high efficiency and energy saving.

System Characteristics

- Electric Control System

- Utilizing KOYO multifunction PLC to control processing sequence.

- To set, modify, and monitor data through touch screen panel.

- Using our original 64 point axis wall thickness control system.

- Utilizing Eurotherm DC speed controller, which is stable, reliable and energy efficient.

- Transducer is the brand name products.

- Hydraulic System

- Utilizing proportional servo control system to controlling the movement of the two stations separately, which is stable, reliable and energy efficient. Pumps and valves are all brand name products.

- Pneumatic System

- Utilizing special blowing processing so that air amount and pressure is steadily controlled during the production. Pneumatic elements are brand name products.

- Clamping Unit

- Utilizes 3-platen 3-pulling rod structure so that large uniform clamping force can be applied. Also, it easy to change mode.

- Blowing Unit

- Versatile with features like expanding, stretching and pulling, diameter locking and blow pin rotation, etc. It can be changed according to customers’ requirements.

- Blow Molding System

- The extruder screw and die head are designed and manufactured with CAD/CAE/CAM tools and experience. Double runners design, easy to change color, high quality parison. The steel for the die is 38CrMoAlA.

SCJ50C/SCJ50CT/SCJ50TA Extrusion Blow Molding Machine System

Applications

SCJ50C was the first one of QC’s extrusion blow molding machine. The development of QC’s blow molding machine technology developed the seventh generation, SCJ50C is the witness.

SCJ50C can be use to make 20 L – 50 L high molecule weight High Density Polyethylene (HMW-HDPE) blow containers.

SCJ50T/TA especially uses to make 3D small & medium automobile pipes. Its maximum length can be 1.2 m.

System Characteristics

- Electric Control System

- Utilizing KOYO multifunction PLC to control processing sequence.

- To set, modify, and monitor data through touch screen panel.

- Using our original 64 point axis wall thickness control system.

- Utilizing Eurotherm DC speed controller, which is stable, reliable and energy efficient. Transducer is the brand name products.

- Hydraulic System

- Utilizing proportional servo control system, which is stable, reliable and energy efficient. Pumps and valves are all brand name products.

- Pneumatic System

- Utilizing special blowing processing so that air amount and pressure is steadily controlled during the production. Pneumatic elements are brand name products.

- Clamping Unit

- Utilizes 3-platen 3-pulling rod structure so that large uniform clamping force can be applied. Also, it can produce wide-scope products.

- Blowing Unit

- Used to make closing drum and big drum. It can be changed according to customers’ requirements.

- Blow Molding System

- The extruder screw and die head are designed and manufactured with CAD/CAE/CAM tools and experience. Double runners design, easy to change color, high quality parison. The steel for the die is 38CrMoAlA.

SCJC50×2 Extrusion Blow Molding Machine System

Applications

To make 20L-50L high molecule weight High Density Polyethylene (HMW-HDPE) double layers small bulk containers for high cleanliness requirements liquid chemical packaging and foodstuff packaging. It features high-output with energy and material saving.

System Characteristics

- Electric Control System

- Utilizing KOYO multifunction PLC to control processing sequence.

- To set, modify, and monitor data through touch screen panel.

- Using our original 64 point axis wall thickness control system.

- Utilizing Eurotherm AC speed controller, which is stable, reliable and energy efficient.

- Hydraulic System

- Utilizing proportional servo control system, which is stable, reliable and energy efficient. Pumps and valves are all brand name products.

- Pneumatic System

- Utilizing special blowing processing so that air amount and pressure is steadily controlled during the production. Pneumatic elements are brand name products.

- Clamping Unit

- Utilizes 3-platen 3-pulling rod structure so that large uniform clamping force can be applied, easy to change mould. Also, it can produce wide-scope products.

- Blow Unit

- Can produce closed drum and large mouth drum.

- Blow Molding System

- Utilizes a high efficient extruder, it features high output and good quality, the main material is 38CrMoAlA. The double-layer die head are designed and manufactured with CAD/CAE/CAM tools and experience. Design reasonable, structure compact, easy to change color, high strength parison. The inner color is pure color for the products, and out color can be changed according to requirements.

SCJ50B×2 Double-Station Extrusion Blow Molding Machine System

Applications

To make high molecule weight High Density Polyethylene (HMW-HDPE) small & medium bulk containers in large volume. The maximum container volume is 50 L. The output rate is 1.5 times faster than the same size equipment with single station.

System Characteristics

- Electric Control System

- Utilizing KOYO multifunction PLC to control processing sequence.

- To set, modify, and monitor data through touch screen panel.

- Using our original 64 point axis wall thickness control system.

- Utilizing Eurotherm DC speed controller, which is stable, reliable and energy efficient. Two different sizes of goods can be produced on the left and right stations simultaneously, which is a pioneering technology in the world.

- Hydraulic System

- Utilizing proportional servo system to separately control actions of the two stations; which is stable, reliable and energy efficient.

- Pneumatic System

- Utilizing special double-station blowing processing, which can separately control blowing process parameters of the two stations. Pneumatic elements are brand name products.

- Clamping Unit

- Utilizes 3-platen 3-pulling rod structure, right-left station utilizing oil cylinder driving to realize precision position control.

- Blow Molding System

- Utilizes a high efficient extruder for homogenous, it features high output and good quality. The extruder screw and die head are designed and manufactured with CAD/CAE/CAM tools and experience. The steel for the die is 38CrMoAlA.

Mould

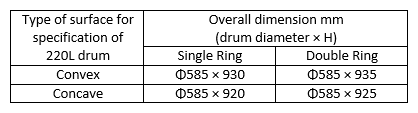

220L Single/Double L Ring Drum Mould

- The plastic blow moulded 220L single/double L ring drum has been developed as one of our major products. In 1993, the first set of mould for 220L double L ring drum was produced in our factory.

- In 1995, our 220L single/double L ring mould and SCJ230 Plastic Blow Moulding Machine were awarded the second prize in National Advance of Science and Technology Progress. Todate, we have manufactured and sold over 400 sets of our moulds and machines.

- After more than 30 years of technological improvement and innovation, the L-ring designs for different kind of drums have matured and are quite standardized.

- Several decades after Qinchuan successfully launched its 220L mould to the market, such moulds are now made locally instead of importing. The quality and performance of the products have now reached international standards.

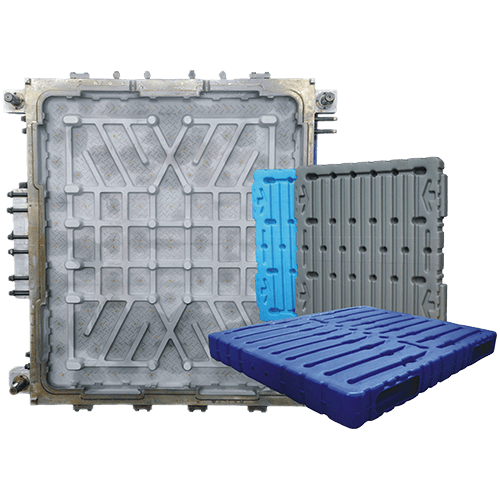

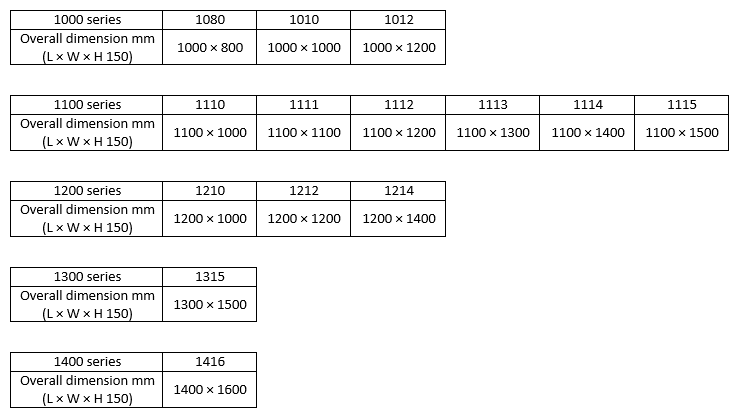

Pallet Mould

- Qinchuan pallet moulds cover a complete range of specifications. Our pallet product “1600×1400mm” which features multi-directional supporting forks is currently available locally and was originally designed by Qinchuan.

- The biggest advantage of the Qinchuan pallet mould is that one mould can support various product specifications. Two way forking and four way forking can be configured which results in a lower cost of investment to the end user.

- The body of the mould is made of Aldural while high quality heat treated die steels are used for the production of mould joints. This guarantees the edge strength and the sharpness of the tip which helps easy deflashing and prolongs the life of the mould.

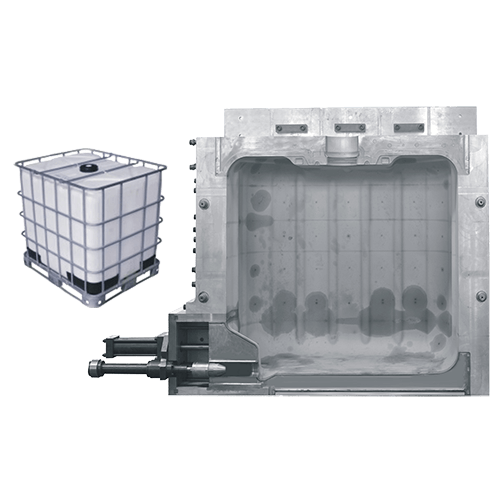

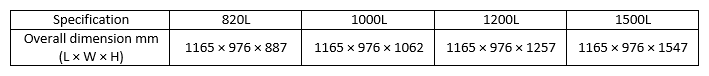

IBC Container Mould

- The unique designs of four critical parts for our IBC mould are registered patents in China.

- Easier container moulding, patent No. ZL200920033766.4

- Design of modular protective support for container, patent No. ZL200920033764.5

- Design of dust guard at the drainage port. patent No. ZL200920033765.X

- Design of top pin cut unit for IBC drainage port. patent No.:ZL2007200316315

- 1500L blow moulded plastic inner container is the largest one in China.

- The body of the mould is made of Aldural and the cooling water channels are well-spaced. This features a good cooling effect and ensures the high quality of the product.

- The drainage port is moulded in one piece. The technology of the top pin cut of the drainage port is a unique design in China which guarantees good leak-proofing properties and improves the inner quality of the drainage port. This decreases the manufacturing cost for the customers as well.

- Thanks to the composite property, the IBC mould can accommodate rapid changes for different products specifications within one set.

Open Top Drum Mould

- The body of the mould is made of Aldural and the tool edge is made of high quality die steel which guarantees a sharp edge. This improves the service life of the mould.

- The unique design of venting holes around the bung, cover and trim and well designed structure make its surface smooth.

- Features good leak-proofing between cover, bung and seals, outstanding anti-impact characteristics and stacking.